A visit to power2max

20.11.16 11:49 13.6452016-11-20T11:49:00+01:00Text: Reini Hörmann (Factory), NoPain (NG)Photos: Erwin HaidenIn the past few years, power2max has become one of the most successful manufacturers of bicycle power meters on the international market. A factory visit gave us deep insight into the complex subject of power meters for bicycles.+ First impressions of the new power2max NG20.11.16 11:49 13.6852016-11-20T11:49:00+01:00

A visit to power2max

20.11.16 11:49 13.6852016-11-20T11:49:00+01:00 Reini Hörmann (Factory), NoPain (NG) Erwin HaidenIn the past few years, power2max has become one of the most successful manufacturers of bicycle power meters on the international market. A factory visit gave us deep insight into the complex subject of power meters for bicycles.+ First impressions of the new power2max NG20.11.16 11:49 13.6852016-11-20T11:49:00+01:00

In the past few years, power2max has become one of the most successful manufacturers of bicycle power meters on the international market. The name stands for durability, a high level of precision, a truly fair price-performance ratio and, since September of this year, an overall Vuelta win. Our factory visit granted us deep insights into the complex subject of power meters for bicycles.

The story of power2max (development, marketing and distribution) and Saxonar (development, production and logistics) began in 2006. Marco Rockstroh and his friend and business partner Andreas Görnitz then worked in the automotive industry: they produced high-quality wireless products for a well-known car manufacturer. It was precisely this know-how that proved to be so enormously valuable for the inventors of the power2max sensor. At this stage, they had already been intensely devoting themselves to the subject of measuring cyclists’ power output. Many ideas were developed and then rejected. But soon, a certain concept attained a realistic form that both were equally convinced by: they wanted to develop a power meter that would be perfectly suited for both hobby riders and professional athletes. The objectives were clear:

The sensor must deliver reliable and reproducible data – under all weather conditions. The construction should include no moving parts in order to have a product with almost no wear. Its handling and operation needs to be simple; you should concentrate on the essentials in training and competition – not on bells, whistles and sales gimmicks. And all of this at an affordable price.

These experienced technicians' extremely high expectations created a few problems that had to be solved; the path to a finished product was not a simple one. To reach the objectives, development was divided into the main areas of mechanics, electronics and software. So four years passed until finally the "Classic Sensor” could be presented at Eurobike in 2010. The first product of this fledgling company was already completely developed, systematically tested and certified. From then on in, everything went extremely fast: the sales numbers increased regularly from the beginning, and after Middle Europe new areas of distribution such as Australia, New Zealand and Asia were added; North America and South Africa followed. The spectrum of application was expanded and the sensors were then made compatible for mountain bikes. A remarkable narrative of success thus began...

BB goes p2m

We directly intrude on a meeting of the responsible managers and then the coffee break of the employees. In the common kitchen, we are immediately made to feel at home, and we get a hot coffee to strengthen our spirits and the meeting is interrupted for us.

Andreas, who always has a good mood and immediately takes over the task of showing us around, proudly tells us that this newly renovated building equipped with modern technology used to be a dairy. The hill that the Saxonar/power2max company property occupies to be called “Käseberg” [cheese hill]. A huge red-brick smokestack next to the factory is a witness to past eras.

The mood is relaxed throughout the entire building. No one is hectic, but they are constantly developing and producing. Almost all of the employees live nearby. Andreas also set up his family home only a few kilometers away from his workplace; in contrast, Marco drives to work from Chemnitz. Most of the time, he explains, he develops and works at home in front of his computer.

Both the municipalities and the families who have a secure and well-paid workplace profit from the company’s location. Marco and Andreas don’t just place their bets on coolly calculated profits and certainly not on an artificially overblown business model – they bet on the tried and true. And it is precisely this philosophy that is reflected in the products they produce, whose individual parts are almost exclusively produced in Germany. Simple but still attractive to the eye, durable, exact and “reduced” to maximally precise measurements, compatibility and ease of use.

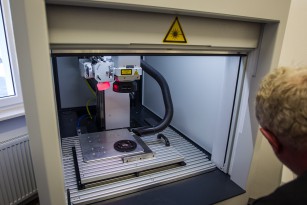

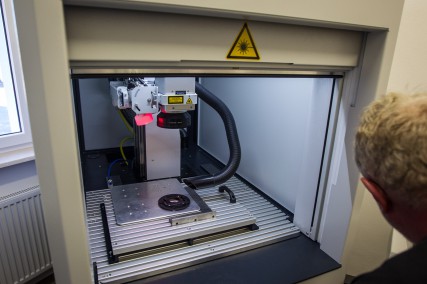

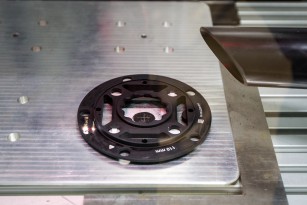

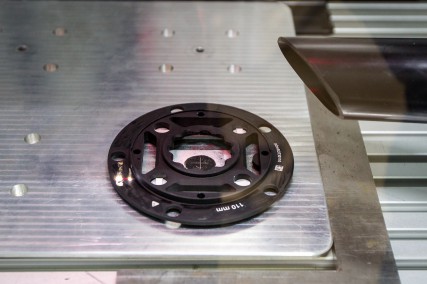

Production

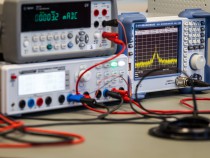

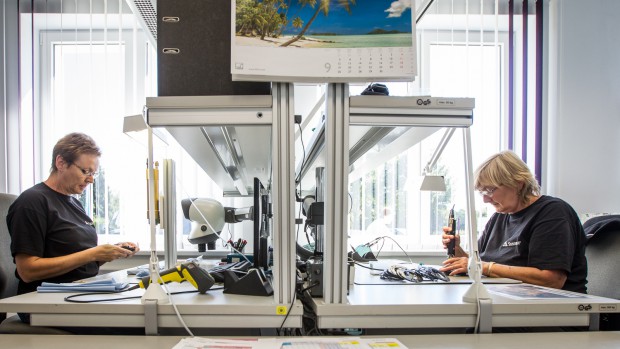

We have already been convinced of the quality and precision in many tests – however, we are almost swamped by all the technical innovations and information that we are confronted by. We had never thought that so many people could be involved in the development of such a sensor, that so many work hours have to be invested, “just” to create a training tool for cycling on a daily basis. And that every detail has to be examined so excruciatingly if it is going to really be that precise.

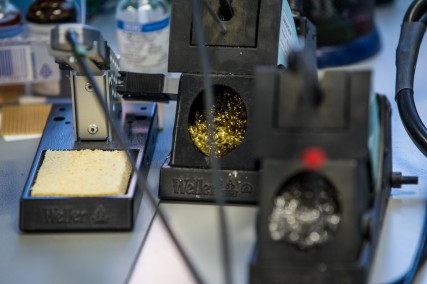

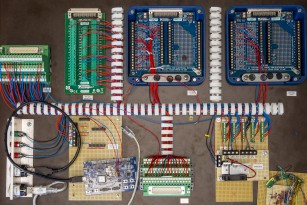

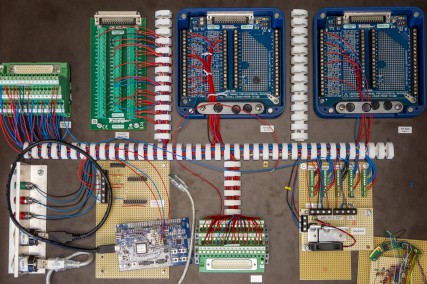

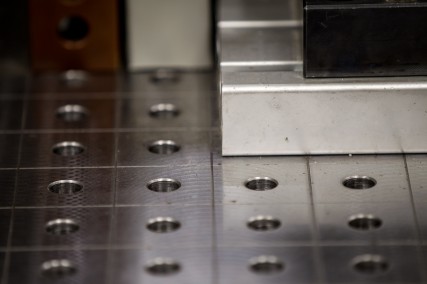

Even minimal moisture in the strain gauges’ environment causes imprecision; also, the positioning of these gauges is of essential importance. Step by step, we witness the creation of a type S sensor. Well-trained people are working at each step of the way, at each station. There are hardly any automated operations; no robot arms are washing or implanting computer motherboards, but still – or maybe precisely because of this – they are producing at a remarkably high level of quality that is unique throughout the world.

"High Tech, Long Life"

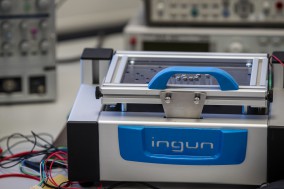

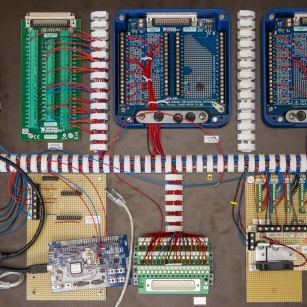

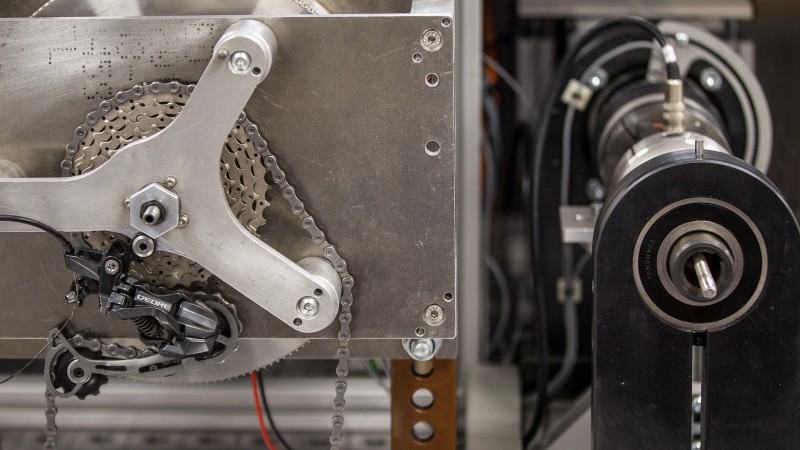

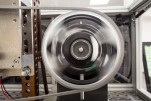

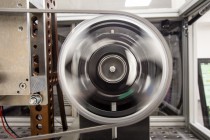

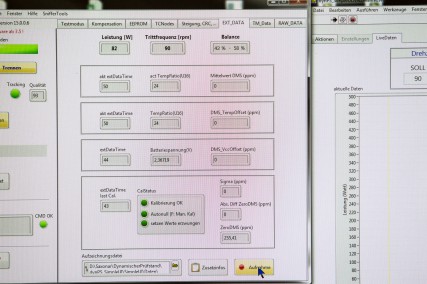

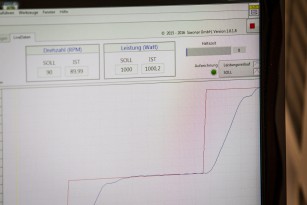

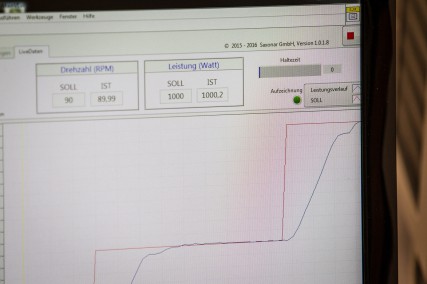

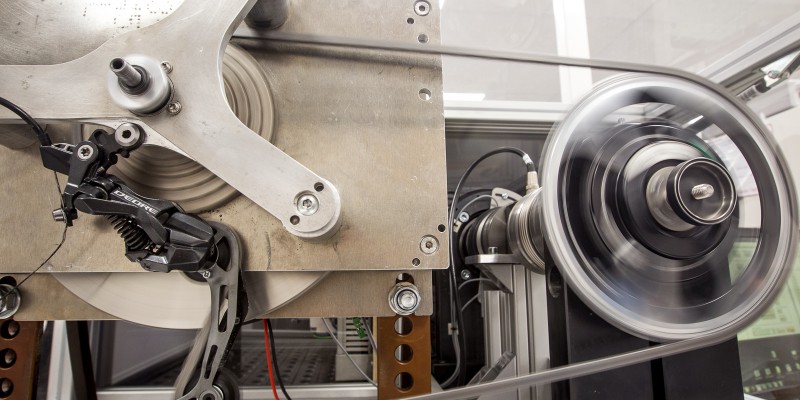

Man-made by power2maxpower2max – Dynamic Test Bench

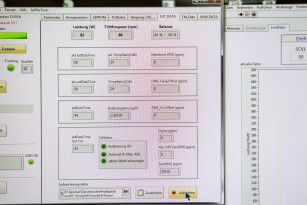

Certain proof that even a humane business philosophy with a handshake approach can lead to the highest levels of product quality is delivered shortly thereafter at the completey new company-own dynamic test bench (and which was developed at a high cost). We arrive just in time - the responsible technician is testing the durability and above all the precision of a NG sensor. NG stands for "new generation” - the current peak of company evolution, according to Marco. This sensor had just been tested for material fatigue by the Institut Zedler. If one were to calculate its lifetime in kilometers, the technician says, the sensor in front of us has done about 200,000 to 400,000 kilometers. This value means that its life expectancy has run out, but Zedler found no material fatigue in the sensor whatsoever. It was still operational.

After a recalibration, a major test begins on the dynamic test bench; it is meant to show how precise or imprecise such a massively used sensor still is. It is pointed out to us that this is an individual test and that a different sensor with these hours of operation could potentially produce different results.

But still, we are impressed - the test protocol presents unbelievable results. The sensor's measurements correspond with the calibrated display of the test bench almost to the watt. At our request, the test is repeated - again with the same result. The NG shows precise values down to almost one watt. Then, Marco really wants to know what it can do. He places the dynamic test bench at its maximum load. According to him, watt values beyond 700 watts have the most effect on material fatigue, so the probability was high that the old sensor could break under a full load. With a great deal of respect, we all step back, despite the protective covers, and then... nothing happens. Even additional attempts at destroying the sensor fail. The test bench ends each respective protocol without having created any damage to the sensor whatsoever.

Distribution

The tour is completed at calibration – before being packaged for sale, each sensor is brought up to a state of highest precision at a self-built station and then tested for accuracy by a “guard”. If there is an error in calibration or testing, the sensor is rejected. As a rule, a power2max sensor never needs to be calibrated again; in contrast to the 2% tolerance of the previous power meter, the NG measures generated watts with a precision of 1%.

We were not allowed to take photos of the static calibration bench, since it is an absolutely unique high-tech measuring station and thus a company secret. At power2max, all sensors are calibrated on a “stand-alone” basis; i.e. without cranks, chainrings, bolts or a chain. In this way, the given high precision can be guaranteed regardless of chainring size, material stiffness, crankarm length, etc. Customers can thus change their configurations as often as they want without the power meter having to be newly calibrated.

The day that will certainly remain in our memories ended with a bike ride during which we could get a first impression of the NG. Finally, the only thing there is left to say is that even though the company is run in an extremely professional and modern way, no corners are cut in terms of compassion or humanity.

First impressions of the new p2m NG (by NoPain)

The opportunity was ideal, and so I immediately installed a p2m NG power meter from the pre-production series with an FSA K-Force Light crank. Since then, I have trained over 1,000 kilometers in all kinds of wind and weather. Here, emphasis lies on the words “all kinds”; two thirds of the time, it rained and was cold: optimum conditions for equipment that needs to defy temperature drift and be waterproof.

But one thing at a time. Before taking my first ride, I plugged it in for a few hours just to make sure. The NG has an integrated rechargeable battery with a running time of approximately 150 hours that can be charged via micro-USB and a standard cable. This means: the two fiddly little screws, battery cover and thin rubber O-rings no longer need to be dealt with. In addition, in case of emergency, a micro-USB cable is definitely easier to find than a Renata CR2450N battery.

Pairing to my bike computer was simple as always. Since the new NG sends out power data with both ANT+ and Bluetooth Smart protocols, I joined and tested it in parallel with two mobile devices: the Garmin Edge 520 and a Wahoo Elemnt. During the duration of the test, it was neither possible to find any interference nor could any difference in the data from the devices be determined, despite comprehensive and exhaustive comparisons.

p2m NG features

Battery - The power2max NG is run with a rechargeable battery. Battery running time is approximately 150 hours and can be charged through the micro-USB port and the supplied standard cable.

ANT+ / Bluetooth – Power data is sent per ANT+ or Bluetooth to a bike computer or smartphone. The firmware can also be updated per Bluetooth.

Accuracy & TC+ - The power2max NG measures power with an accuracy of +/- 1%. The four strain guages, which are placed and oriented in different ways, join with the new spider construction to create higher precision and almost no temperature drift. However, the NG is also equipped with Temperature Compensation plus. In this proven procedure to compensate temperature influences, each power meter goes into a refrigerator where the individual characteristic temperature curves are determined and recorded between -20 to +70 °C. This way, the risk for drift should be close to zero.

NG Metrics - The NG measures the following data: power, pedal cadence, right-left distribution, torque, pedaling efficiency/smooth pedaling.

Simple2use² - Automatic re-zeroing, no battery changes, cadence determination without external magnets, chainring changes do not influence accuracy.

Built2resist - The NG power meter provides reliable power data – always and everywhere. It is waterproof, almost completely free of wear and very robust.

Ride with Style – There are rings and battery covers in a variety of colors in order to optimally match the power meter to existing cranks or bicycles.

Made in Germany – power2max power meters are developed in Germany and manufactured by hand to the highest standards of quality with minimal environmental impact.

In general, the p2m NG has a far more lively watt display (one second interval) that reflects what is happening in reality very well – i.e. the display data fits better to the subjective effort as well as the topography than other manufacturers’ past equipment or power meters. After a short period of acclimatization, I was able to ride with this setting and keep to the desired watt zones. I believe the smoothed watt display (three second intervals) is no longer necessary for the NG, but it is an issue of personal preference.

The new NG after 1.000 Kilometers

After only doing outdoor rides, I am not in a position to evaluate the increased precision of +/- 1% – of course, the values were always plausible, but for a real control there was no reference device with the same precision. One positive impression was the clearly reduced lag on the display of cadence; the sensor’s new design, improved algorithms and a faster accelerometer are responsible for that. The display lags by what subjectively seems to be about two seconds, what I find acceptable and probably also the reason for the quicker or more lively watt display data.

Thanks to the numerous rides in the rain, the NG was able to prove itself in terms of waterproofing. Of course, 1,000 kilometers are not enough in order to award it the Bikeboard.at “IPX7” certification – but it should at least do very well here.

Almost to be good to be true: the new NG is more precise, weighs less, has new features and an inboard battery – without a single bug? Not quite, since during my last ride I observed constant, sudden and significant drops in watt values – despite a slight uphill grade, constant cadence, regular frequency and constant subjective effort – guaranteed without spindowns, shifting or other external influences. The mega bug was apparently found – I immediately started analyzing the situation including examining the documentation and informed the manufacturer. But they were aware of the mistake, the software had already been corrected and a new firmware update was available for download. The NG’s software can easily be updated per smartphone (without screws, connections or even sending it in).

One can assume that, by the time the product goes on the market, (almost) all teething problems will be eliminated. And if not, the customers can do it themselves with a smartphone app.

| BB goes p2m |

| Production |

| power2max – Dynamic Test Bench |

| Distribution |

| First impressions of the new p2m NG (by NoPain) |

| p2m NG features |

| The new NG after 1.000 Kilometers |

| Links |